![]() is a registered trademark owned by Flutec Hydraulics. Our company was formed in Changzhou City of the People’s Republic of China with the mission of supplying world-class hydraulic cylinders and hydraulic systems to various industrial sectors around the world.

is a registered trademark owned by Flutec Hydraulics. Our company was formed in Changzhou City of the People’s Republic of China with the mission of supplying world-class hydraulic cylinders and hydraulic systems to various industrial sectors around the world.

In 1995, Our company started designing and manufacturing the first cylinder in-house. In 2010, we exported the first hydraulic cylinder to the abroad market. Macrodyne has completed numerous installations throughout China mainland and abroad since then.

At present, our overseas customers mainly come from the following countries and districts ( USA, Canada, Germany, Belgium, Russia, Israel, Belarus, South Africa, Kenya, Saudi Arabia, Indonesia, Singapore, etc…)

Our factory floor space exceeds 38,000 Sqr. meters and our 20 cranes provide us with the capability to manufacture cylinders and components weighing up to 300 metric tons. From conception to installation our engineers, factory staff, and salesmen strive to ensure that our customers receive the very best in quality products and service.

Our manufacturing facility is capable of producing hydraulic cylinders up to the following dimensions:

Bore Diameter – 3,000mm / Rod Diameter – 2,500 mm / Stroke – 20,000mm / Pressure – 250Mpa

The Typical Applications:

Press Manufacturing, Machine Manufacturing, Aluminum Casting System, Mobile Hydraulics, Hydropower Plant, Mining and Cement Mill, Ship Lock, Offshore and Marine Crane, Jack-up System, Split Hopper System, Piling Barge, Port Equipment…

We source raw steel materials exclusively from the most reputable and quality-approved suppliers in China such as Chengdu Pangang, Xingcheng Special Steel, Hunan Valin Steel, China Baowu Steel Group, Jiangsu Shagang Steel, etc.

We at Macrodyne invite all customers to consider our facilities for your next hydraulic project.

Macrodyne excels in technical expertise, in fields such as custom-designed cylinders, extra-large cylinders, and heavy-duty, very high-speed or zero-leakage technology cylinders. Our means of production are particularly impressive, with gantry and portal milling machines, large grinding machines, vertical honing, polishing machines, welding machines, etc. Most of our machines are digitally computerized (CNC).

Macrodyne can design any type of custom-designed hydraulic cylinders, per the customer’s requirements, as long as it fits in our wide manufacturing capabilities, which are:

Bore diameter( I.D.): Up to 3,000mm / 120inches

External diamter (O.D.): Up to 4,000mm / 155inches

Length: Up to 20,000mm / 800inches

Turning & Boring: Up to 3,000mm /120inches external diameter, Up to 20,000mm /800inches in length

Honing ( horizontal): Up to 3,000mm/120inches inside diameter, Up to 20,000mm /800inches in length

Milling & Drilling: Up to 2,000mm/80feet in length, Up to 5060mm /17 feet in height, Up to 2350mm/8feet in width

Grinding: Up to 2,500mm / 120inches diameter, Up to 20,000mm /800inches in length

Polishing: Up to 2,500mm / 120inches diameter, Up to 24,000mm /80feet in length

Welding: TIG/GTAW ( Gas Tungsten Arc Welding), MID/GMAW(Gas Metal Arc Welding), SAW( Submerged Arc Welding)

Maximum crane overhead lifting capacity: 100 Tons

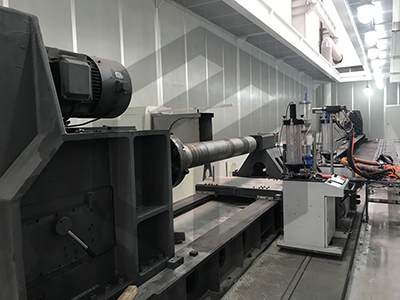

Test Bench

Macrodyne received an ISO 17025 Laboratory Certification certified by the world-recognized International Laboratory Accreditation Cooperation. Putting them to the forefront among cylinder producers.

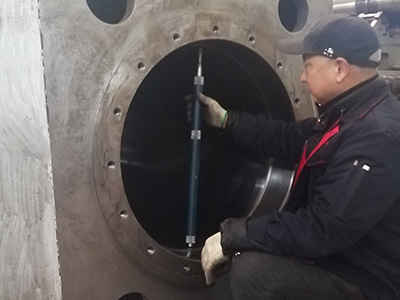

Honing Machine

Macrodyne has highly efficient and accurate Honing machine facilities to provide machining from 20mm to 1500mm in diameter and over 7000mm in length. These advanced machines also supply to the customers who need this service particularly.

Various kinds of Large Lathe

Macrodyne is large lathes that can manufacture various kinds of cylinders because they have a maximum swiveling radius from standard size to 1500mm and over 10M in length.

General Kinds of Lathe

Macrodyne utilizes different kinds of precise lathe equipment to undertake all kinds of lathe processing works with several fixtures and tools to process the spare parts of the cylinder.

Grinding Machine

Macrodyne applies various kinds of grinding machines which can grind the different sizes of cylinder rods from standard diameter up to 2,000mm and its length can be over 20m.

Machining Center

To produce special shapes of cylinders and machinery, Macrodyne owns #3-50-#6 centralized machining equipment with a wide range of processing techniques and accuracy rates.

CNC lathe

Macrodyne has a wide range of sizes of CNC lathes, from #2 to #7. With such high technical equipment, Macrodyne is doubtless to mass-produce various kinds of components of a cylinder with top quality.

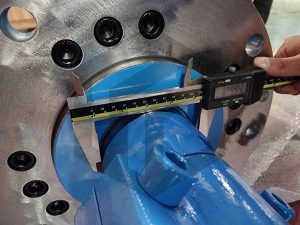

Our quality control is based on ISO9001 to design and implement; as the result, we have a quality plan.

Based on the quality plan, we execute the quality control operations which include material testing reports, dimension inspection reports, and function test reports.

The above procedures enable the buyers to monitor us easily and to minimize the time and money on monitoring.

To achieve the goal of real cost down, we offer quality products at low prices; plus there is no quality control budget needed from our customers.

Each product of Macrodyne represents the ideal synthesis of the most modern technology, thorough execution, and decades of experience.

The demands for such high-quality products are high, the reliability has set upper limits worldwide.

In order to achieve and maintain such a high-quality level continuously, Macrodyne uses state-of-the-art methods and devices.